Views: 2 Author: Site Editor Publish Time: 2020-04-13 Origin: Site

Plastic pallets offer exceptional durability and are about 10 times longer than wooden pallets. Its structural reliability greatly reduces the damage consumption of the tray and the damage of the material on the tray due to the damage of the tray. Plastic pallets are lighter than the same wooden pallets, thus reducing weight and reducing transportation costs.

As a result, food grade plastic trays are becoming more widely used and used more frequently. Some people may want to know what material it is made of, let's talk about it.

List of article content:

What is Food Grade Plastic Pallet?

What material is it made of?

Conclusion

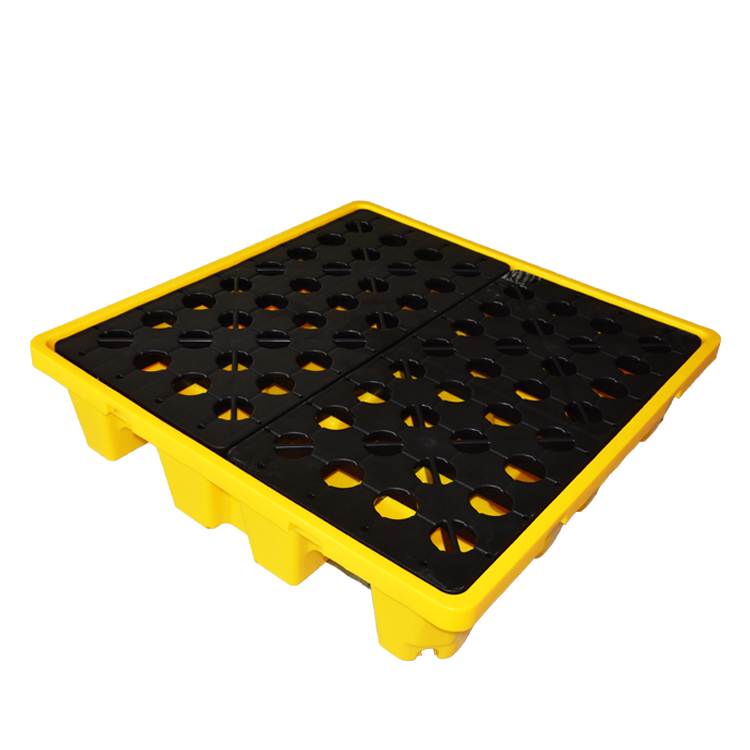

The food-specific plastic tray has the advantages of safety, hygiene, beauty, no nail thorn, tasteless, non-toxic, easy to clean and disinfect, corrosion-resistant, mildew-free, non-combustible, etc. It meets the national food hygiene inspection standards and is recognized by the import and export customs and quarantine bureaus of various countries. It belongs to the world's green environmental protection products, and is exempt from inspection.

1. PET

Plastics are usually used to produce plastic bottles, beverage bottles and other products. People often buy plastic water bottles, carbonated beverage bottles are polyester packaging products and belong to food-grade safe plastic materials.

Potential safety hazard: Polyester is only suitable for normal temperature or cold drinks. It is not suitable for overheated food. If the temperature is too high, the bottle will release toxic substances, which may lead to cancer. If polyester bottles are used for a long time, toxic substances will be automatically released, so plastic beverage bottles will be thrown away immediately after use, and should not be used for long-term loading of other foods, so as not to affect health.

2. PP

PP plastic is one of the most common plastics. It can be made into plastic packaging for any product, such as food special plastic bags, food plastic boxes, food straws, food plastic parts, etc. It is safe, non-toxic and resistant to low temperature and high temperature. PP is the only plastic that can be placed in a microwave oven and has high strength and folding resistance (50,000 times). It will not break under high altitude within -20C.

Characteristics: Hardness is below 0PP, stretchable (two-way pull), pulled into a triangle, bottom seal or side seal (envelope bag), barrel. Transparency is worse than OPP.

3. HDPE

Plastic is commonly known as high-density polyethylene, which has a high use temperature and good hardness, mechanical strength and chemical resistance. It is a non-toxic and safe material and is often used in the manufacture of plastic containers for food.High-density low-pressure polyethylene Highdensity polyethylene is brittle and is often used as a vest bag.

Safety hazard: The plastic container made by HDPE has the characteristics of not easy to clean, so it is not recommended to recycle. It is best not to put it in the microwave for heating.

4. LDPE

Lowdensity polyethylene, soft. The products made with it are odorless, odorless, non-toxic, and matte. Commonly used in food plastic parts, food packaging composite film, food wrap, medicine, pharmaceutical plastic packaging.

Safety hazard: LDPE is not heat resistant. Generally, when the temperature exceeds 110C, hot melt will occur. Such as: household food wrap not to heat the food in the bag, in case of avoiding the grease in the food, it is easy to dissolve the harmful substances in the wrap.

5. PS

It is often used to make bowls of instant noodles boxes, fast food boxes, disposable food packaging boxes, etc. , with good cold resistance.

Potential safety hazard: polystyrene box cannot be placed in microwave oven to prevent toxic substances from being released at too high a temperature. Acid and alkali resistance is poor, so it is not suitable for holding acidic food, avoiding decomposition of carcinogens.

6. PC

Plastics can be used to make sports kettles, bottles, etc. Widely used in plastic containers, is a safe material.

Potential safety hazard: bisphenol A (harmful substance) remains in the computer. The higher the temperature, the more it is released and the faster the speed is. Therefore, do not use a personal computer water bottle to hold hot water, so as not to increase the speed and concentration of bisphenol A (if any).

7. PVC

Currently rarely used for food packaging, it is best not to buy

Safety hazard: When using this material, it is easy to have harmful substances, and even it will be released during the manufacturing process. When toxic substances enter the human body with food, it may cause diseases such as breast cancer and birth defects. Currently, containers of this material have been used less for packaged foods. If you are using it, don't let it get hot.

Plastic pallets can be cleaned and reused, or recyclable, adding a lot of environmental friendliness. Of course, it also goes hand in hand with the theme of promoting environmental protection around the world. If you want to know about food grade plastic trays, feel free to contact us.

We have built a professional Q C team to accurately inspect every raw material and every process of production.

Copyright 2019 Qingdao C N plast Co., Ltd. All Rights Reserved .